Concentrated Solar Power

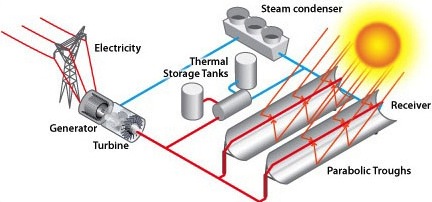

Parabolic Trough

Roughly 60 percent of the applications under review by the BLM call for the use of a parabolic trough system (Figure 1). Parabolic trough plants achieve at least a 25 percent1 capacity factor, which means about a quarter of the sun’s energy that is captured by the system is converted to usable electricity.

This system is composed of:

- Long parabolic shaped mirrors made of 4-millimeter thick glass with high transmittance properties and include a reflective silver layer on the backside of the glass.2

- A receiver tube that runs the length of the mirrors.

- A tracking support structure and drive components that control the movement of the collector throughout the day in relationship to the position of the sun. Altogether these components are called a solar collector assembly (SCA). The SCA’s can sit approximately 25 to 30 feet above ground.

How the system works:

- The mirrors direct the sun’s light to a focal point where the energy is concentrated onto to the linear receiver tube, or heat collection element (HCE).

- The HCE is a stainless steel tube that is coated with a special absorber surface that maximizes transfer of heat from the sun to the heat transfer fluid (HTF) traveling inside the tube.

- The HTF is usually comprised of a either a high-temperature oil or a mixture of water and ethylene glycol.3

- The HTF is supplied to the power plant where it passes through a series of heat exchangers, turning water into high-pressure steam that drives a Rankine steam turbine.

- The HTF is then returned to the solar collector field to be heated once again, creating a closed loop system.

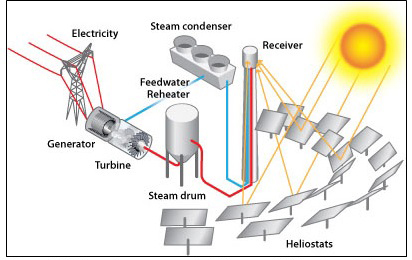

Power Tower

There are several applications that call for the use of Power tower systems (Figure 2). Power tower technology has a capacity factor of 34 to over 40 percent.4

How the system works:

- A large field of mirrors, called heliostats, track the sun.

- A tower collects light concentrated by the heliostats onto a central receiver on top of a tower. Tower heights range from approximately 300 to 650 feet.

- HTF, composed of either water or molten nitrate salt, moves through the receiver and is heated to temperatures over 500 °C.

- The heated HTF is then sent to a heat exchanger where water is turned into steam, which then drives a turbine generator.

More advanced systems that use molten salt as the HTF can take advantage of the higher heat capacity of the fluid and can store the heat energy, which allows the system to continue to generate electricity during cloudy weather or at night. Thermal storage allows systems to continue to generate electricity for several hours longer compared to those without, which effectively increases the systems’ capacity factor. Additionally, power tower systems typically employ dry cooling as opposed to wet cooling technology, requiring less water to operate the system.

The amount of solar energy collected is a function of the number of heliostats installed. However, as the number of installed mirrors increases, the height of the tower must also increase. Determining the optimal tower height and field size is driven by economies of scale. It is relatively inexpensive to increase equipment size once a project has incurred its initial fixed costs of installation. Larger plants, therefore, tend to be more economical. Additionally, the heliostats can be mounted in ground with up to five percent slope because they do not rely on a linear collector to heat the HTF. Like the parabolic trough systems, HTF is an integral part of the power tower system.

Dish/engine

There are a few applications that call for the use of dish/engine systems (Figure 3). A capacity factor figure for dish/engine systems is not available.

This system is composed of:

- A large mirrored dish (also known as a solar collector).

- A receiver that consists of a series of tubes that are filled with a heat transfer medium. The medium is usually either hydrogen or helium.

- A small engine. A Sterling engine is the most common type of heat engine used in dish/engine systems.

How the system works:

- The dish is mounted on a tracking system that follows the sun throughout the day.

- Concentrated sunlight heats the fluid in the receiver and transfers energy to the engine.

- The engine uses the heated fluid to move pistons and create mechanical power.

- The mechanical power is then used to run a generator to produce electricity.5

- The waste heat from the engine is dissipated by a radiator system similar to one found in a car.

- The cooled medium is then recycled to the engine and the process repeats.

A capacity factor figure is not available for dish/engine systems because there are no large installations of dish/engine systems in operation to date. However, a leading Sterling engine system manufacturer has achieved a dish/engine system efficiency of about 31 percent.6 Using this value as a proxy, a comparison of capacity factors of the various concentrated solar power technologies is summarized in Table 1.

| Technology Type | Capacity factor (%) |

|---|---|

| Parabolic Trough | 25 |

| Power Tower | 34 |

| Dish Engine | 31 |

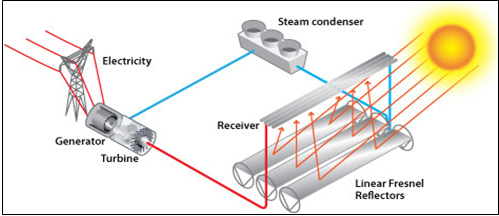

Linear Fresnel lens

One technology that should be monitored, but does not yet appear in any applications, is a Linear Fresnel reflector systems (Figure 4). These systems are similar to parabolic trough systems in that a set of mirrors reflects the sun’s energy onto a linear receiver. The major difference is that with a Fresnel system the mirrors are either flat or slightly curved and are mounted on a tracker that focuses the sun light onto a fixed receiver tube system that sits above the mirrors. A central receiver, the tallest component in this system, rises approximately 50 feet above the ground. Few power plants using this technology have been installed and therefore little data is available related to plant efficiency and operational reliability. However, with efficiency improvements on the horizon, more attention is being given to this technology.7 Linear Fresnel systems have lower production costs due to the use of flat mirrors compared to the curved mirrors used in parabolic trough systems. Another major difference is that water can be converted directly into steam in the long receiver tubes, eliminating the need to install additional heat exchange equipment. If the plant economics are found to be favorable or if linear Fresnel plant efficiencies can be increased to a point where it is comparable to parabolic systems, then these systems may become the dominant technology type found in utility- scale solar plant facilities.

1 National Renewable Energy Laboratory (NREL) Home Page , NREL: TroughNet - Parabolic Trough Solar Field Technology, http://www.nrel.gov/csp/troughnet/solar_field.html.

2 National Renewable Energy Laboratory (NREL) Home Page , NREL: TroughNet - Parabolic Trough Solar Field Technology, http://www.nrel.gov/csp/troughnet/solar_field.html.

3 Process Register, "Heat Transfer Fluids," Process, Energy and Greater Manufacturing Industries Manufacturer Directory - Buy, Sell, Trade with Industrial Suppliers, Exporters and Importers, http://www.processregister.com/Heat_Transfer_Fluids/Suppliers/pid1467.htm

4 SolarPACES, http://www.solarpaces.org/CSP_Technology/docs/solar_tower.pdf.

5 National Renewable Energy Laboratory (NREL) Home Page, "NREL: Learning - Concentrating Solar Power," http://www.nrel.gov/learning/re_csp.html.

6 Treehugger, "Improved Solar Power Dish with Stirling Engine Made by Car Parts Suppliers ," http://www.treehugger.com/files/2009/07/stirling-energy-systems-solar-po... electricity.php.

7 CSP Today, "Hovering in the Wings: Linear Fresnel Technology | CSP Today," News, Events and Business Intelligence for the CSP Industry,http://social.csptoday.com/industry-insight/hovering-wings-linear-fresnel-technology.