Photovoltaic

Roughly 40 percent of the applications submitted to the BLM call for the use of photovoltaic technology.

Photovoltaic power generation is one of the cleanest and environmentally benign methods of generating electricity. Benefits of photovoltaic power generation include:

- PV power generation does not produce emissions or hazardous waste and does not consume water during operation.

- PV power generation systems are generally easier to construct and install compared to conventional fossil or nuclear power plants, making them attractive to utility power providers.

- PV power generation systems can be more easily expanded as demand increases.

The two main types of PV technologies that are being considered for utility-scale solar power generation today are flat plate and thin film PV.

Flat Plate Photovoltaics (PV)

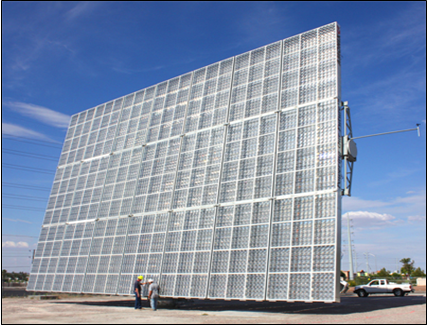

According to the DOE, the most common solar array designs use flat plate PV modules (Figure 1).1 Flat plate PV modules are used in fixed systems or integrated into more sophisticated designs that include tracking systems that follow the sun’s trajectory across the horizon throughout the day.

Flat plate PV devices can be made of various types of semiconductor materials, the most common of which is silicon. Silicon can be single (or mono)-crystalline, multicrystalline or amorphous, where crystallinity is a measure of how perfectly ordered the atoms are in the crystal structure. Most flat plate PV modules use solar cells that are made from either single-crystalline or amorphous silicon.

- Solar cells made from single-crystalline silicon are more efficient but also tend to be the most expensive because of the purity of silicon material.

- Solar cells made from amorphous silicon are less efficient but are usually cheaper. Solar panels that utilize amorphous silicon solar cells are currently the most common

To date, crystalline silicon-based flat plate PV technology is able to achieve module conversion efficiencies between 15 and 20 percent.2 Module conversion efficiency is a measure of how effectively the sun’s energy is converted directly to electricity by the collection of solar cells that make up a single modular unit. At these performance levels, some solar companies have determined that there is a business case for developing large utility-scale solar facilities using flat plate PV technology.

Thin Film PV

Thin film photovoltaic cells (Figure 2) are usually made of a certain type of polycrystalline material. The three most common thin film materials are:

- amorphous silicon (a-Si),

- copper indium diselenide (CIS) and its alloys,

- cadmium telluride (CdTe).3

Thin film solar cells are produced by depositing very thin consecutive layers of atoms on a flexible substrate. Substrate material can be either glass, stainless steel or various types polymers.

Benefits of thin film PV:

- Thin film production costs approximately half that of silicon-wafer based solar cell production.4

- Thin films use much less material during production compared to silicon-based solar cells and can be manufactured in large-area automated continuous-process equipment.

Costs of thin film PV:

- Thin film PV cells are significantly less efficient compared to single or amorphous-crystalline silicon solar cells.

- CdTe based thin film solar cell module efficiency is currently around 13 percent5, the highest of the three material types. CIS produce modules with an efficiency around 10 percent and a-Si around 8 percent.6

However, research and development in this area is constantly pushing the efficiency of thin film solar cells closer to that of conventional silicon based PV.

Concentrating Photovoltaic (CPV)

Several concentrating photovoltaic system companies are developing technology that can also be used for utility-scale solar electricity generation, however, none of the applications currently proposed for BLM land call for this technology.

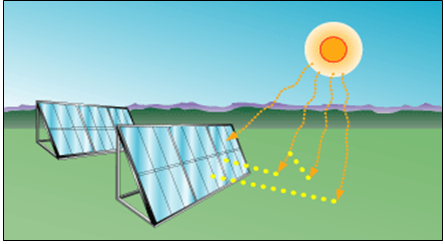

How CPV systems (Figure 3) work:

- A large dish of reflective mirrors or concentrating lenses that direct sunlight onto a photovoltaic surface produce electricity directly from the sun’s energy.

- Modules are installed on a high- precision dual-axis tracking system which ensures optimal operation throughout the day.

- These systems can be configured to concentrate the sun’s energy between two to 500 times.

- High concentration PV (HCPV) systems favor the use of high efficiency, multi-junction solar cell technology because efficiency of these cells rises faster with concentration than do conventional silicon based solar cells.

CPV systems have only recently been installed in utility-scale facilities, and therefore system reliability and lifetime performance data is sparse. However, commercially available CPV systems have demonstrated energy conversion efficiencies of approximately 29 percent.7 A comparison of module efficiencies of the various photovoltaic technologies is summarized in Table 1.

| Technology Type | Module efficiency (%) |

|---|---|

| Flat Plate PV | 15 |

| Concentrating PV | 29 |

| Thin Film | |

| CdTe | 13 |

| CIS | 10 |

| a-Si | 8 |

1 EERE, Solar Energy Technologies Program: Flat-Plate PV Systems, http://www1.eere.energy.gov/solar/flat_plate.html.

2 EERE, Solar Energy Technologies Program: Flat-Plate PV Systems, http://www1.eere.energy.gov/solar/flat_plate.html.

3 EERE, Solar Energy Technologies Program: Thin Films, http://www1.eere.energy.gov/solar/thin_films.html.

4 McKinsey Quarterly, “Evaluating the potential of solar technologies," http://www.mckinseyquarterly.com.

5 EERE, Solar Energy Technologies Program: Thin Films, http://www1.eere.energy.gov/solar/thin_films.html.

6 EERE, Solar Energy Technologies Program: Thin Films, http://www1.eere.energy.gov/solar/thin_films.html.

7 Treehugger, "Improved Solar Power Dish with Stirling Engine Made by Car Parts Suppliers ," http://www.treehugger.com/files/2009/07/stirling-energy-systems-solar-po....