Grading, Hydrological Modification and Vegetation Removal

Grading and slope adjustment are the most common types of landscape alteration for solar facility development. This is due to the relatively inflexible range of slope tolerance for the different solar

technologies. Parabolic trough technology can only tolerate a slope of approximately

three percent or less, while dish/engine and power tower systems can tolerate a grade of up to six percent.1 The higher slope tolerance of dish/engine systems is likely due to the fact that the mirrors are anchored to the ground independently of one another and therefore require less uniform land conditions. Although this may seem like a minor difference, a slight change in the pitch of the land can result in the need to grade a considerably larger portion of the project site.

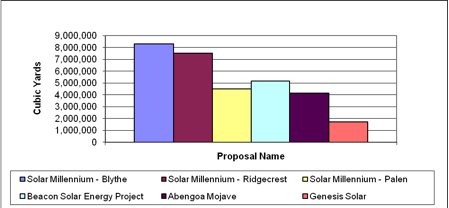

Figure 2 demonstrates the substantial amount of earthwork planned for the construction of solar facilities. For a comparison of the volume of soil that is being removed, if all the soil being moved by the Solar Millennium Blythe project were placed onto a football field, the mound of soil would be over a mile in height.

Grading and slope adjustment techniques:

- Cut and fill– material is cut away from one area of a landscape, such as a slope or hill, and used to fill in another part of the same landscape, such as a low-lying depression.

- Infill– the process of adding additional soil to an uneven desert surface in order to make either a level or low-grade (less than five percent) plane. It is expected that some materials, such as engineering fill, will be imported to the site in order to provide adequate structural support for building foundations, even for those projects that are relying on a predominately balanced grading plan. Engineering fill is different from regular soil since it has specific properties, such as grain size and moisture content, which can make compaction easier.

- Soil compaction- Industrial-level soil compaction will be performed to stabilize the land and sufficiently reinforce it so that it can support the construction of buildings, solar arrays, roads, and fencing. This soil compaction will likely be performed using industrial equipment such as single-drum rollers, reversible plate compactors, or tire rollers.

Other types of site engineering necessary to prepare a project site include erosion control measures, placement of infill, and the redesign of hydrologic features on site such as ephemeral streams and low- lying basins. The redesign of hydrologic features, such as streams, is designed to keep water from pooling next to large pieces of infrastructure and to prevent any flooding from occurring on site during rain events. Most developers only propose the re-routing of hydrologic features that overlap proposed infrastructure. Each of these processes may need to be performed to a varying degree, depending on the technology type that will be placed on the site.

Lastly, most developers propose to clear vegetated undergrowth from the project site, primarily within the solar array field and around the buildings, as these areas represent the greatest threat for wildfires.2,3 Vegetation removal is often a requirement for development in order to meet California’s high standards for fire prevention. This requirement is not likely to vary based on technology type, which means that the ecological implications of this activity cannot be circumvented by utilizing a different type of system.