Wet Cooling

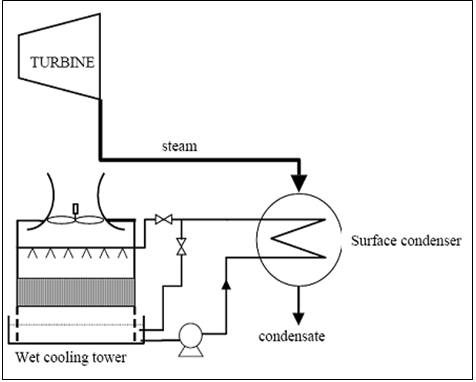

Wet cooling tower (also called “Evaporative cooling” or “Wet re-circulating”)

Wet cooling systems (Figure 1) are the most common technology in new power plants.1 Waste heat is dissipated to air via evaporation of cooling water. The greater the difference between the temperature of the cooling liquid and the temperature of the surrounding air, the greater the potential for evaporative cooling. This thermodynamic property is the reason why wet cooling systems perform better than “dry” cooled systems in areas with ambient temperatures greater than 110 °F. Wet cooling tower systems withdraw between 300 and 700 gallons per MWh, but all of the water withdrawn is consumed.2

The water treatment chemicals and minerals found in the cooling water become more concentrated as the re-circulated liquid evaporates over time. In order to remove particulates and reduce the concentration of salt in the water found in the catch basin, part of the water is discharged and replenished from either surface or ground water supplies. The discharged water is collected in evaporation ponds, which are double-lined to reduce the risk of contaminated water leakage. Some applications include pond designs that do not require the removal of residual solids over the life of the power generation plant. Others account for periodic removal and land-fill disposal of the solids. Several applications call out more specific design requirements that are in accordance with the local Water Quality Control Board, including:

- 60 millimeter thickness liner

- High density polyethylene material

- Synthetic drainage net between double lining as part of the leachate collection and removal system (LCRS)

Monitoring of these ponds to detect the presence of liquid and/or “constituents of concern” is also required according to the CEC. Some applications call for monitoring of the LCRS along with sampling from existing onsite wells. “Constituents of concern” that are to be monitored include chloride, sodium, sulfate, TDS, biphenyl, diphenyl oxide, potassium, selenium and phosphate.

Once-through

Clean Water Act regulations prohibit the use of “once-through” cooling for new power plants due to environmental concerns3 and are not relevant to solar development in California, and therefore, are not discussed in detail in this report.

1 Statement of Kristina M. Johnson, Under Secretary of Energy U.S. Department of Energy before the Committee on Science and Technology, Subcommittee on Energy and Environment U.S. House of Representatives, July 9, 2009.

2 Statement of Kristina M. Johnson, Under Secretary of Energy U.S. Department of Energy before the Committee on Science and Technology, Subcommittee on Energy and Environment U.S. House of Representatives, July 9, 2009.

3 California Energy Commission, Interim Guidance for Desert Renewable Energy Project Development, September 2009, Pg. 24.